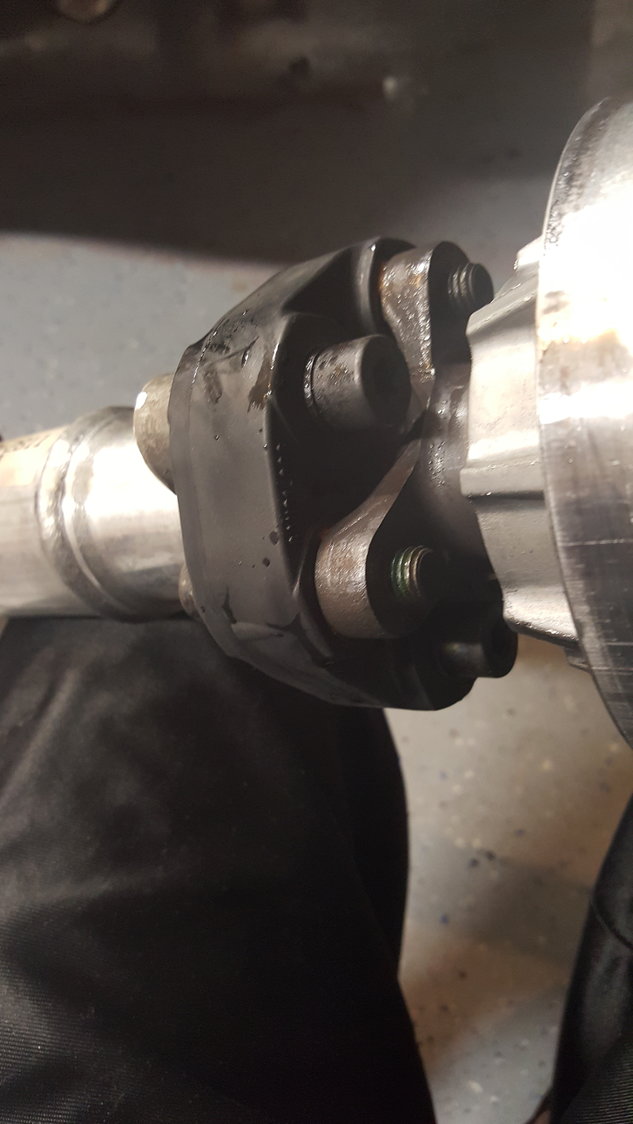

drive shaft coupling failure

That unfortunately has led to many motor and driven-shaft failures due to torsional-fatigue factors. 3 Early failure of the short-lived shaft bearings from age and use.

Driveshaft Coupling Land Rover Forums Land Rover Enthusiast Forum

Shaft couplings are critical parts of any power transmission system providing the smooth transfer of power from one component to another.

. While the most common torsional fatigue cracks start at the sharp corner stress concentration at the bottom of the keyway when couplings are poorly fitted another common appearance is the diagonal shaft crack like that shown in Fig. As per my experience after looking at coupling i think the teeths conditions of coupling indicates fretting wear and tear and then it slipped on the day of incident. The objective of this paper is to study various shafts failure analysis and select the best method to find out the root cause failure of heavy nip roller shaft used in textile industry.

The failure may be coursed by improper installation excessive misalignment and poor coupling selection and so on. Any misalignment at this connection induces a cyclical load on the coupling and causes fatigue and eventual failure. 2 Abnormal wear caused by lack of lubricant packed in coupling.

At Crane Engineering we find the root cause of coupling failure ladders up to one of the following reasons. If the U-joint of your drive shaft rotates too fast or fails to rotate then its a problem with your drive shaft. If your shaft is worn the lubrication system is clogged the fuel pump is clogged and there is a buildup of debris in the engine then you have a high chance of a shaft failure.

Up to 8 cash back Experiencing a significant shudder when accelerating from low speed or a stopped position it can be another sign of failing driveshaft components. 1 Normal torsional pulses generated as the impeller climbs over the pump cam. Maybe Im looking at it wrong but thats what it looks like to me in the pictures.

Following types of rigid coupling are important from the subject point of view. Had to replace my factory rear driveshaft coupling recently has a few small cracks due to age. As with any other part of the system maintenance maximizes coupling life and ensures reliable system operations.

Either that or the u-joint itself is not stable. The result is a drive shaft coupling flange that is stronger truly perpendicular and will not fail. A loose U-joint or bad center bearing within the driveshaft may cause the faltering acceleration.

Put in a new Dorman one and it has destroyed itself in just 2 months. Which resultant into loss of power transmission to tail rotor. B Clamp or split-muff or compression coupling and.

Proton Wira front wheel drive shaft was chosen as the specimen of this analysis 2. Shaft failure maintenance techniques Conveyor heavy nip roller. The female splines should be parallel to the ground and the mating spline shaft on the mower deck.

The Two-Shaft raw water pump shaft couplings will wear and fail due to. The failure mechanism of the drive shaft was caused by the elevated axial and torsional oscillation loads in combination withthejammeddriveshaftspline. Drive shaft is broken from many points.

Most drive shaft manufacturers recommend that tube yoke circle welds be started in line with the tube yoke ear and 180. Symptoms of misalignment include the following. It is used to connect two perfectly aligned shafts.

The situation became severe because an axial horizontal parallel to the crankshaft pump natural frequency and torsionalshaftassemblynaturalfrequencyweresimultaneously. Noise at the coupling Powdered rubber particles or leaking lubricant directly below the coupling depending upon coupling type Process fluid andor oil leaks at the drive driven or both shafts Premature shaft shaft keyway or key fatigue. Some external signs that indicate potential coupling failure include.

β 1 β 2 Angular Misalignment ß1 ß2 The driver and driven shaft centerlines of your equipment must intersect at the center of the drive shaft. Discussion Starter 1 Feb 6 2015. This is because with the passage of time the bearing seal cap can rust.

Youll need to have your drive shaft replaced because you cant drive your vehicle in this condition. Car is a 2007 V6 and had done around 460000km on the factory coupling and if I hadnt stupidly thrown the old one out I would. The cap seals of the bearings could have rust on them.

If the cushioned plate option is followed this is not necessary. Foot of joint coupling measured joint center to joint center distance B is equivalent to approximately ½ to 1. Shaft failure causes the unnecessary shutdowns and leads to heavy production loss.

In such a case the vehicle can no longer be propelled and the. If the drive shafts universal joint revolves very fast or cannot revolve then there is an issue with your shaft. A Sleeve or muff coupling.

You may also hear sounds while the car is shuddering from the worn-out U-joint. Misalignment can be caused by improper installation of the pump and motor pipe strain even bent shafts. The gearbox is unbolted and supported as it is moved clear and can then be lifted clear for inspection on a bench.

If the shaft is to be removed the gearbox oil will need to be drained first. KWS has solved this problem by machining the drive shaft and coupling flange from one piece of solid bar. In order to improve coupling service life you should try best to prevent it prior to its failure.

Up to 50 of damage to rotating equipment is directly related to misalignment. This project presented about a failure of drive shaft in conventional passenger vehicles 1. The cause of driveshaft failure is the result of a combination of factors.

β 1 β 2 The maximum joint operating angles depends upon the. The shaft couplings will also need to be undone for the same reason. Fractures specifically related to drive shaft yokes Improper welding when the drive shaft is assembled can cause tube yoke failures.

A combination of mismatched alignment andor high speed engagement of the pto could certainly cause a catastrophic failure such as this. The first step in preventing drive shaft failure is to replace the shaft. A belt is a looped strip of flexible material used to.

Tail Rotor Drive Shaft Coupling Failure Rotorcraft Engineering Eng Tips

Tail Rotor Drive Shaft Coupling Failure Rotorcraft Engineering Eng Tips

Video Symptoms Of A Worn Or Failing Drive Shaft

Ford Transit Driveshaft Flexible Coupling Lawsuit Filed Carcomplaints Com

New Recall Nov 2020 Driveshaft Flexible Coupling Ford Transit Usa Forum

12 Reasons For Coupling Failure And How To Avoid Them Insight Acorn Industrial Services Ltd

Tail Rotor Drive Shaft Coupling Failure Rotorcraft Engineering Eng Tips

Driveshaft Coupling Land Rover Forums Land Rover Enthusiast Forum

Replacing The Propshaft Coupling Mercedes Benz Forum

Drive Shaft Components Machine Service Inc

Transmission Driveshaft Coupling Cracked Ford Transit Usa Forum

Signs That Your Drive Shaft May Be Going Bad

6 Symptoms Of A Bad Driveshaft And Replacement Cost In 2022

Mercedes Flex Disc Problems Symptoms Cost Mb Medic

Drive Shaft Components Machine Service Inc

Drive Shaft Couplers Corvetteforum Chevrolet Corvette Forum Discussion

Motor Spline Failure Transmission Driveline Hybrid Drive Engineering Eng Tips